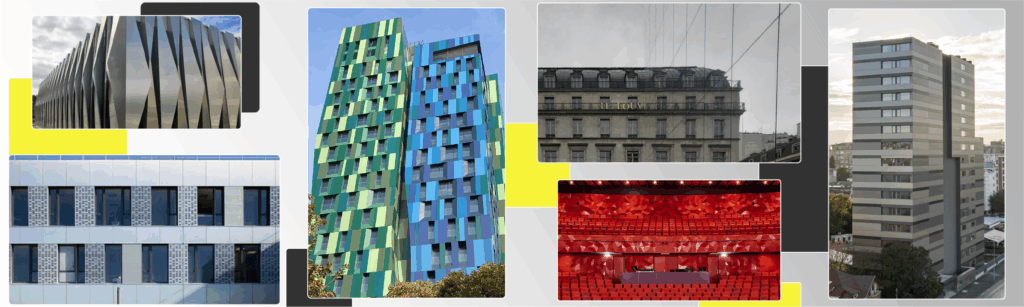

Exterior aluminum panels are advanced cladding systems designed to enhance the durability, aesthetics, and performance of building exteriors. Made from high-quality aluminum alloys, these panels are lightweight, corrosion-resistant, and highly adaptable for a variety of architectural styles.

They are commonly used in commercial buildings, public infrastructure, and high-end residential projects. Due to their low maintenance requirements and long lifespan, they have become a go-to choice for architects and contractors seeking sustainable and modern cladding solutions.

Why Choose Exterior Aluminum Panels for Your Facade?

Aluminum facade panels offer a powerful combination of visual appeal and structural integrity. Unlike traditional cladding materials, they do not warp, rot, or rust, even in harsh environmental conditions. This makes them ideal for projects in coastal or humid areas where moisture can be a constant challenge.

Moreover, these panels come in a wide range of finishes, including anodized, painted, and powder-coated options, allowing for a personalized look that matches your project vision. They can also be fabricated into various shapes and sizes to support creative architectural features such as curves, folds, and perforations.

Benefits of Using Exterior Aluminum Facade Panels

The most significant benefit is longevity. Aluminum is naturally resistant to weathering, UV radiation, and corrosion. With proper coating, it retains its appearance and strength for decades. This means fewer repair costs over time, reducing the total cost of ownership for building managers.

Secondly, these panels support energy-efficient building designs. Many systems are installed with insulation layers behind them, improving thermal performance and reducing energy consumption. In hot climates, reflective aluminum surfaces can significantly lower cooling loads by deflecting solar radiation.

Technology and Fabrication Techniques Behind Aluminum Panels

Modern exterior aluminum panels are fabricated using precision technology such as CNC machines, laser cutting, and folding systems. This allows for the accurate production of intricate designs while maintaining panel integrity and surface quality.

Surface treatments play a critical role. PVDF coating, for example, provides superior color retention and resistance to chemicals, making it suitable for urban areas with pollution. Additionally, honeycomb and composite core designs are used to enhance structural performance without adding excessive weight.

Top 5 Exterior Aluminum Facade Panel Products in the Market

ALUCOBOND® PLUS

A top choice for high-rise and commercial buildings, ALUCOBOND® PLUS features a mineral-filled fire-retardant core. It offers high impact resistance, flexibility in design, and a wide selection of finishes. Ideal for those who want both performance and aesthetics.

Reynobond® Aluminum Composite Panels

Reynobond panels are known for their lightweight core and superior flatness. They’re frequently used in curtain walls, building envelopes, and signage. Their protective coating technology helps maintain color integrity even under extreme weather conditions.

Larson® FR by Alucoil

Larson® FR panels provide a fire-resistant solution with a polyethylene or mineral core. They come in metallic, solid, and textured finishes, offering great creative control. Perfect for facade renovation and new builds with strict fire safety regulations.

ALPOLIC® FR

ALPOLIC® FR panels combine versatility with safety. These panels are often used in educational institutions, hospitals, and airports. Their smooth finish and rigid structure make them suitable for flat or curved installations.

FunderMax Exterior Panels

While not purely aluminum, FunderMax panels include aluminum-reinforced elements and are known for their high-pressure laminate structure. They’re excellent for ventilated facades and are available in over 100 design options.

Use Cases: How Aluminum Facade Panels Solve Real-World Problems

One of the most common problems in building design is degradation from environmental exposure. Exterior aluminum panels address this by providing a protective shell that resists water, UV, and temperature fluctuations. In regions with high rainfall or coastal winds, these panels protect the underlying structure and insulation.

They also solve issues related to outdated building aesthetics. By installing aluminum panels, property owners can instantly modernize their facades without extensive reconstruction. This is especially valuable in commercial properties seeking to attract tenants or customers.

Where to Buy and How to Order

You can purchase exterior aluminum panels from authorized distributors, online retailers, or direct from manufacturers. Below are some trusted links to begin your purchase:

Shop ALUCOBOND® Panels

Buy Reynobond® Products

Order Larson® FR Panels

Get ALPOLIC® Samples

FAQ

1. Are aluminum facade panels energy-efficient?

Yes. Many panel systems include an insulating layer that improves the thermal performance of buildings.

2. How long do exterior aluminum panels last?

With proper coating and maintenance, they can last over 30 years.

3. Can aluminum facade panels be recycled?

Absolutely. Aluminum is 100% recyclable, making these panels an eco-friendly cladding option.