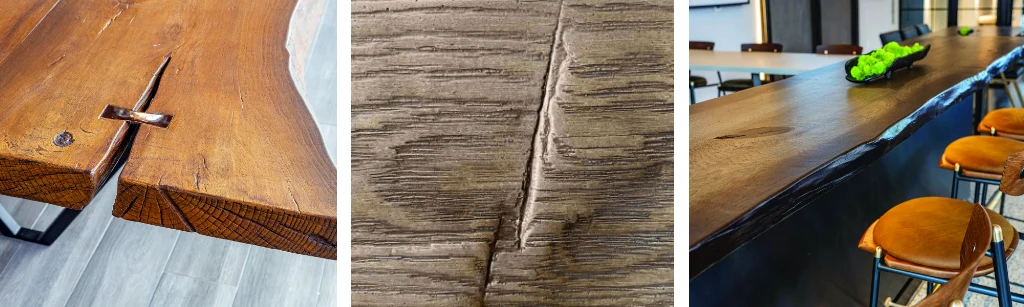

Wood-formed concrete is a design technique that captures the warmth and texture of natural wood within a concrete surface. This innovative method uses wood planks or wood-textured form liners to imprint grain and structure into wet concrete during forming. As a result, builders and designers achieve a unique aesthetic: the visual appeal of timber paired with the strength and resilience of concrete.

From architectural facades to retaining walls, this technique has become increasingly popular in both residential and commercial construction. It’s especially appealing for modern rustic designs, urban landscaping, and sustainable building projects seeking both beauty and performance.

Benefits of Wood-Formed Concrete in Architecture and Landscape Design

Aesthetic Excellence with Timeless Character

One of the most compelling reasons to use wood-formed concrete is the striking natural appearance it creates. Whether it’s the fine grain of cedar or the rugged texture of reclaimed timber, wood patterns in concrete add visual interest and warmth to any space. This aesthetic enhances environments like civic plazas, public parks, hospitality venues, and custom homes.

Importantly, these surfaces are not only beautiful they are also enduring. Unlike real wood, which degrades over time, wood formed concrete withstands decades of exposure with minimal wear.

Low Maintenance with Long-Term Cost Savings

Concrete with wood textures offers long-term savings on maintenance. Real timber requires treatments against insects, rot, and UV exposure. In contrast, wood-formed concrete is inert and impervious to these threats. There’s no need for staining, sealing, or replacement.

This makes it ideal for areas that demand durability, such as retaining walls, pedestrian walkways, building exteriors, and infrastructure near water.

Sustainable and Eco-Conscious Construction Wood-formed concrete supports green building strategies. It allows architects to achieve the look of wood without consuming forest resources. Moreover, many projects use reclaimed wood to create the forms, giving old lumber a second life as a mold. This aligns with sustainable practices and contributes toward LEED certification.

RECKLI Wood Formliners

RECKLI offers premium elastomeric form liners that produce precise wood textures in concrete. Their wood series includes options like vertical plank, bark patterns, and reclaimed board forms. These liners are reusable, flexible, and easy to apply across cast-in-place or precast concrete installations.

RECKLI’s products are widely used in commercial and civic projects due to their fine detail and durability. Their liners capture the organic depth of wood grain, making them ideal for designers looking to combine elegance with rugged performance.

Fitzgerald Formliners

Fitzgerald Formliners offers a diverse selection of wood-themed textures for concrete. From barnwood to milled cedar, their formliners replicate rustic and contemporary timber finishes. These liners are crafted for repeated use and maintain high-definition detailing even after multiple pours.

Used frequently in public spaces and transportation projects, Fitzgerald’s liners help create visually engaging structures like bridge supports, park walls, and exterior façades. Their ability to mimic wood with high accuracy has made them a popular choice among engineers and artists alike.

Advanced Formliners – Woodgrain Series

Advanced Formliners delivers highly detailed woodgrain molds using durable elastomers. Their product line includes aged vertical wood, horizontal siding, and charred wood finishes. These liners are known for their consistency and precision.

Often used in modern architectural walls and boutique construction, the wood-formed medconcrete finish brings texture and uniqueness to any structure. The liners work especially well with stain and pigment systems to further replicate natural wood tones.

Custom Rock Wood Series

Custom Rock’s Wood Series offers concrete form liners with rich woodgrain impressions. These textures include rough-sawn timber, weathered planks, and cedar board finishes. Made from urethane for longevity, the liners are suitable for repeated use in cast-in-place applications.

These liners are commonly specified in transportation infrastructure, commercial architecture, and institutional landscaping. Their realistic wood finishes enhance the visual appeal of large concrete installations without sacrificing durability.

Bush Concrete Formliners

Bush Formliners provide affordable yet high-quality wood form liners for decorative concrete. With options like rough cedar and aged wood slats, their textures are ideal for retaining walls, sound barriers, and feature walls in both residential and public environments.

Bush Formliners’ products are widely praised for their ease of use and ability to replicate natural textures accurately. Their form liners support pigment treatments, allowing designers to fine-tune the final appearance.

Use Case: Solving Design and Durability Challenges with Wood Formed Concrete

In urban design, exposed concrete is often seen as cold or institutional. Wood-formed concrete solves this problem by introducing warmth and visual richness. For example, city planners now use it to soften the appearance of concrete retaining walls and transit structures.

In residential settings, wood-formed concrete allows homeowners to achieve a rustic cabin look in climates where real wood would warp or rot. Similarly, hospitality venues utilize it to create textured statement walls that endure high foot traffic and weather exposure.

Its applications include:

- Façade cladding on commercial buildings

- Feature walls in interior design

- Landscape elements in parks and gardens

- Infrastructure like culverts and sound walls

- Artistic installations and signage backdrops

Where and How to Buy Wood-Formed Concrete Products

These products can be purchased directly from manufacturers or through authorized construction supply distributors. Most companies offer sample kits and technical consultations to help select the best pattern for your project.

Buy from RECKLI

Shop Fitzgerald Liners

Order from Advanced Formliners

Get Custom Rock Products

Contact Bush Formliners

FAQ

1. Can wood-formed concrete be used indoors?

Absolutely. It is commonly used for interior accent walls and fireplaces to deliver a warm, textured finish with the resilience of concrete.

2. Does wood-formed concrete require special maintenance?

Not at all. It is low-maintenance compared to real wood. Occasional cleaning and optional sealing are generally all that’s required.

3. Can the concrete be stained to look like different wood species?

Yes. Many manufacturers offer guidance on stains and sealers that mimic oak, walnut, cedar, and more to meet your design goals.